Munich is Germany's automotive home to BMW, top-tier suppliers, and world-class engineers. But most factories still aren't using AI to its full potential.

GO-Globe's automotive AI systems Munich help you optimize production, prevent quality issues, predict equipment failures, and coordinate complex supply chains. Real results for automotive manufacturers who can't afford downtime or defects.

The industry is changing fast. Electric vehicles. Autonomous driving. Mass customization. Stricter sustainability rules. You need automotive-grade quality at competitive costs while adapting quickly.

Our manufacturing software Munich gives you intelligent systems that adapt to changes, prevent defects before they happen, coordinate supply chains automatically, and keep learning to improve continuously.

Smart Production Planning Our intelligent production Munich AI analyzes thousands of variables to generate optimal schedules, coordinate just-in-sequence deliveries, balance workloads, and adapt when disruptions occur. Most manufacturers improve on-time delivery by 25-35% while cutting inventory costs 20-30%.

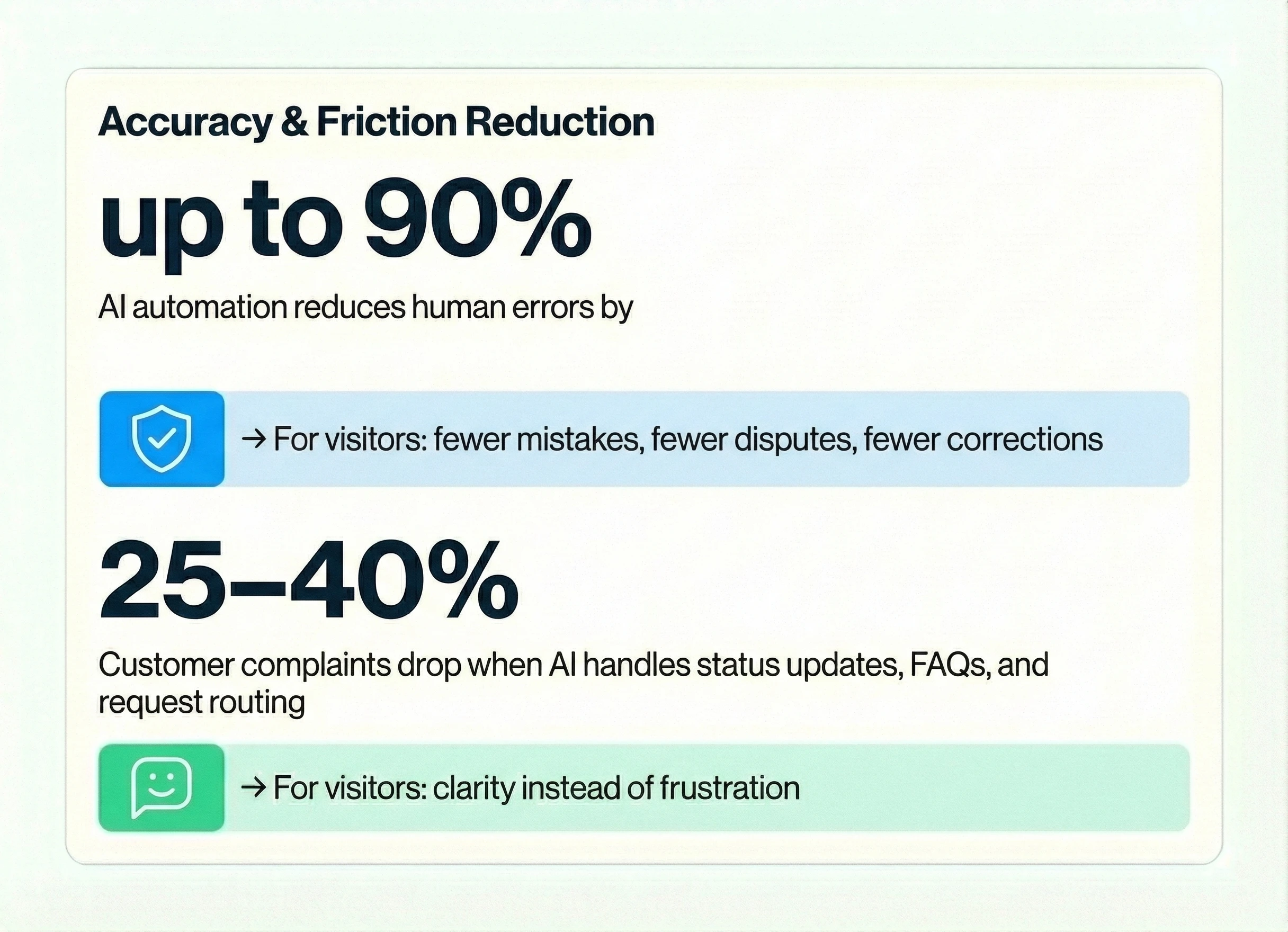

Zero-Defect Quality Real-time monitoring identifies conditions that cause defects. Computer vision inspects with superhuman accuracy. Predictive analytics forecast issues early. Automated systems adjust processes to maintain specs. Defect rates drop 50-70%. Warranty costs plummet.

Predictive Maintenance IoT sensors and machine learning predict equipment failures days or weeks early. Schedule maintenance during planned downtime instead of emergency stops. Cut unplanned downtime by 40-60% and reduce maintenance costs 25-35%.

Intelligent MES Integration Our MES AI Munich makes your Manufacturing Execution System actually smart. AI-powered control adjusts parameters automatically, guides operators, identifies bottlenecks in real-time, and handles exceptions. Production throughput improves 15-25%.

Supply Chain Coordination Comprehensive intelligence for demand forecasting, supplier monitoring, logistics optimization, and risk management. Just-in-sequence coordination delivers components in exact assembly sequence. Supply chain costs drop 15-25%.

Digital Twin Technology Test everything virtually before physical implementation. Optimize processes, train operators, and validate planning without production disruption. Commissioning time drops 30-50%.

Automated Quality Inspection Deep learning computer vision detects defects invisible to humans, measures with micron-level precision, and verifies assembly at production line speeds with 99%+ accuracy.

Energy Management Intelligent monitoring and optimization reduce energy costs by 15-25% while tracking carbon footprints for sustainability reporting.

Munich's automotive ecosystem is unmatched—BMW headquarters, hundreds of specialized suppliers, Technical University of Munich, Fraunhofer research institutes, and Bavaria's supportive government programs. This creates ideal conditions for automotive AI systems Munich with access to expertise, talent, and innovation networks.

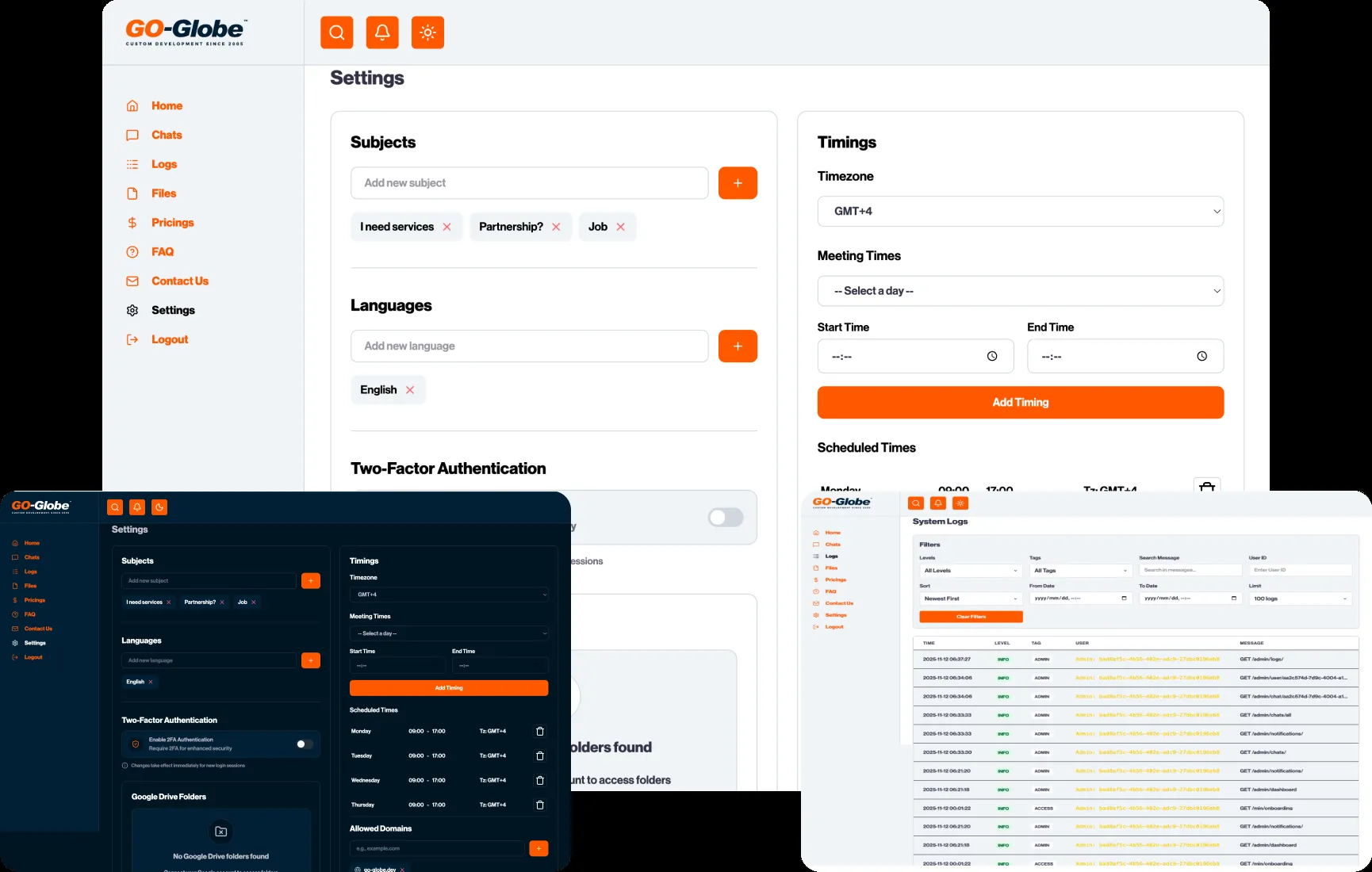

Assessment: We analyze your production, equipment, quality systems, supply chain, IT/OT architecture, and automotive-specific requirements (IATF 16949, VDA standards, OEM requirements).

Strategy & Roadmap: Comprehensive plan balancing quick wins with long-term initiatives, sequenced logically with clear metrics.

Pilot Implementation: Focused pilots demonstrate value and validate approaches before broader deployment.

Integration: Seamless connection with automotive PLCs, MES platforms, ERP systems (SAP Automotive), quality systems, and supplier communication platforms using automotive protocols.

Quality Validation: Rigorous testing, IATF 16949 compliance documentation, and quality gate approvals before production release.

Training: Comprehensive programs for operators, technicians, engineers, and management in German and English.

Continuous Improvement: Ongoing support, optimization, technology updates, and capability expansion.

Full compliance with IATF 16949, VDA standards, ISO 26262 functional safety, IEC 62443 cybersecurity, GDPR, and customer-specific requirements from BMW, Audi, and Mercedes. Comprehensive traceability supporting recalls and warranty management.

Leading Munich automotive manufacturers have revolutionized production with GO-Globe's automotive AI systems Munich and manufacturing software Munich solutions.

Implementation takes 6-18 months depending on scope. We offer flexible approaches for various starting points.