Germany leads the world in smart manufacturing, and Frankfurt sits right at the heart of this revolution. At Go-Globe, we help automotive manufacturers and industrial producers like you use AI to work smarter, cut costs, and stay ahead of the competition.

Our Industry 4.0 AI ERP Frankfurt solution isn't just another software upgrade. It's a complete transformation of how you run your factory floor.

Your current ERP system tells you what happened yesterday. Our intelligent system predicts what will happen tomorrow and fixes problems before they start. Think of it as having a super-smart assistant that never sleeps, constantly watching your operations and making things better.

Traditional systems record data. Our smart manufacturing ERP Frankfurt learns from that data and takes action.

Your production planner is good, but they can't analyze thousands of variables at once. Our AI can. It looks at customer demand, machine capacity, material availability, worker schedules, quality requirements, and energy costs all at the same time. Then it creates the perfect production schedule and adjusts automatically when things change.

For automotive manufacturers, this means handling complex assembly lines where every car might be different. The system coordinates everything with your suppliers so parts arrive exactly when you need them.

Equipment failures cost you millions in lost production and emergency repairs. Our manufacturing AI ERP Frankfurt watches your machines 24/7 through sensors that track vibration, temperature, energy use, and performance. The AI spots problems weeks before they cause breakdowns.

The results? You'll cut unplanned downtime by 30-50% and your machines will last longer too.

Instead of checking random samples and fixing defects after they happen, our system watches quality in real-time. It spots tiny trends that humans miss and adjusts your processes automatically to keep everything perfect.

We use computer vision that's more accurate than human inspectors and never gets tired. Perfect for meeting Germany's tough zero-defect standards.

Your supply chain is complicated. Our enterprise AI ERP Germany makes it simple. The system predicts when suppliers might have problems, suggests backup options, and keeps just the right amount of inventory. You'll reduce inventory costs by 20-30% while actually improving your service levels.

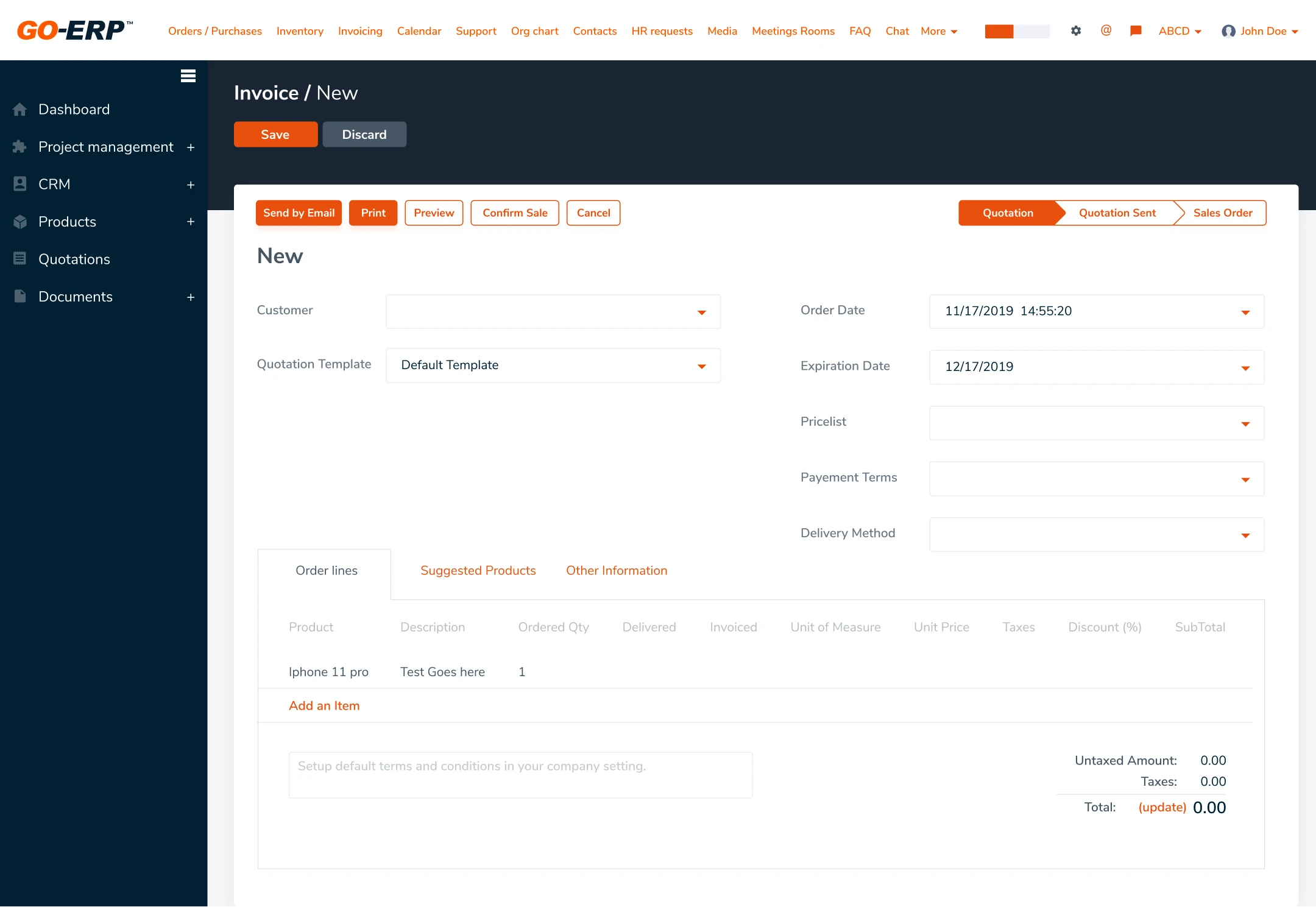

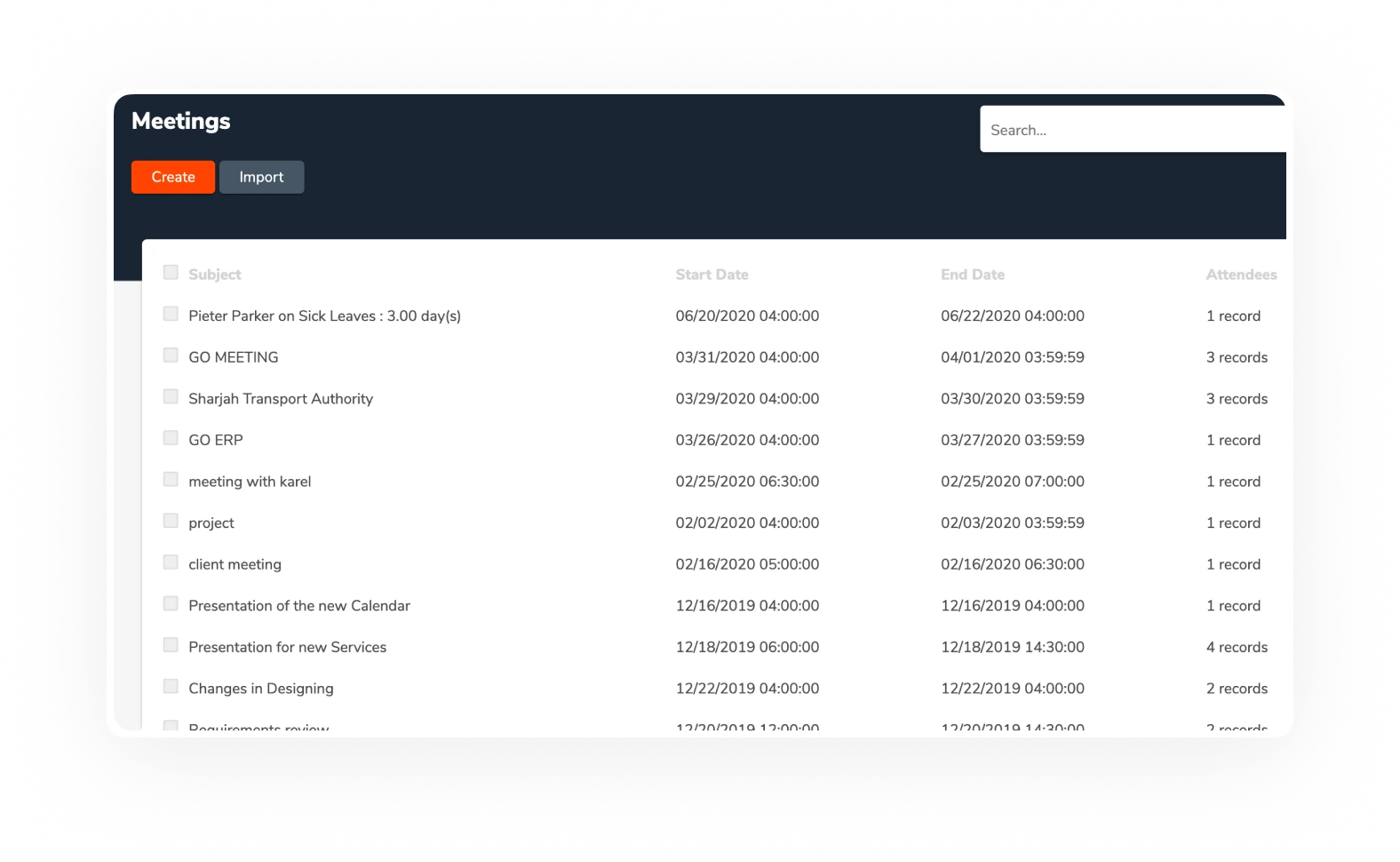

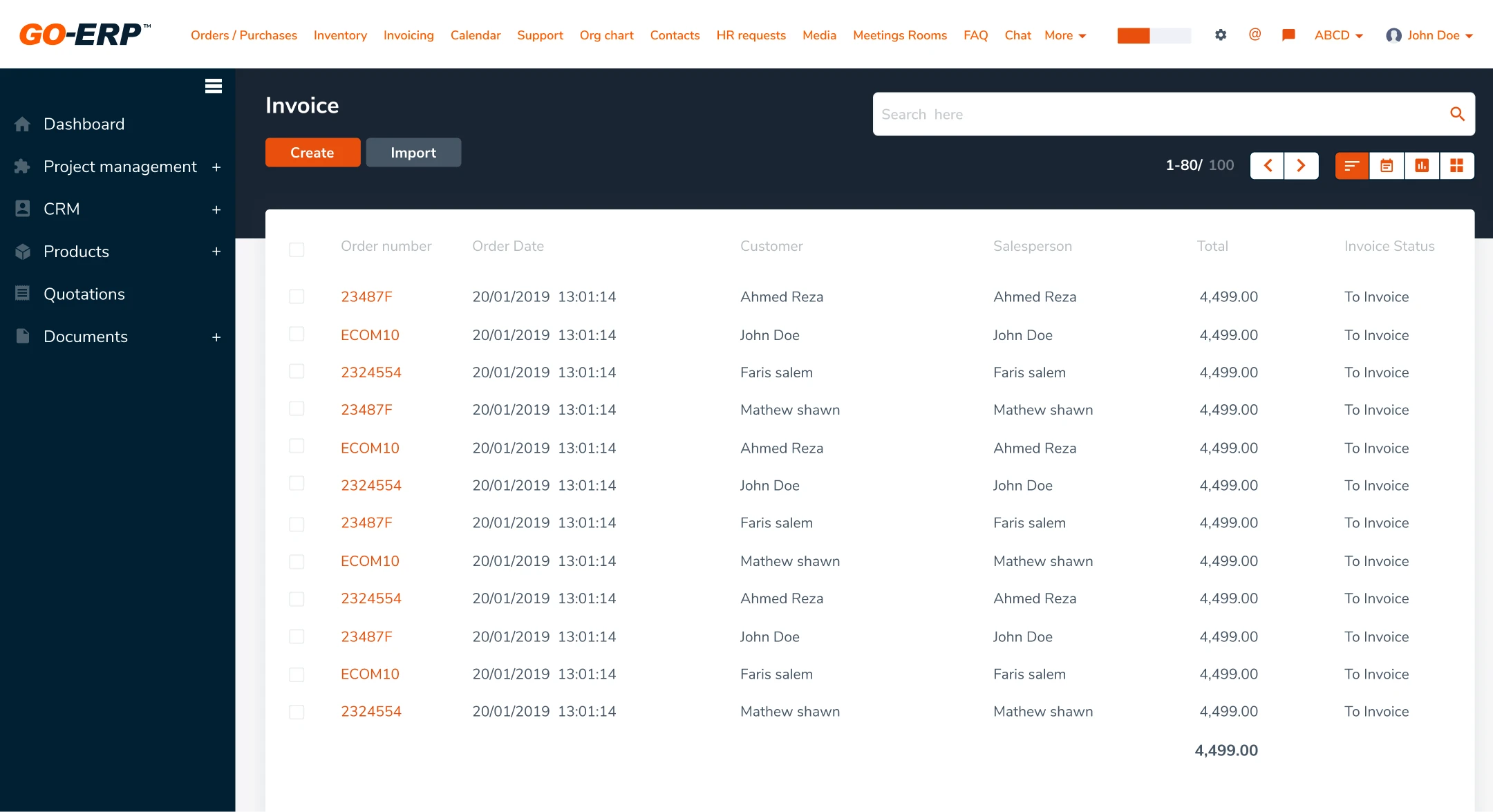

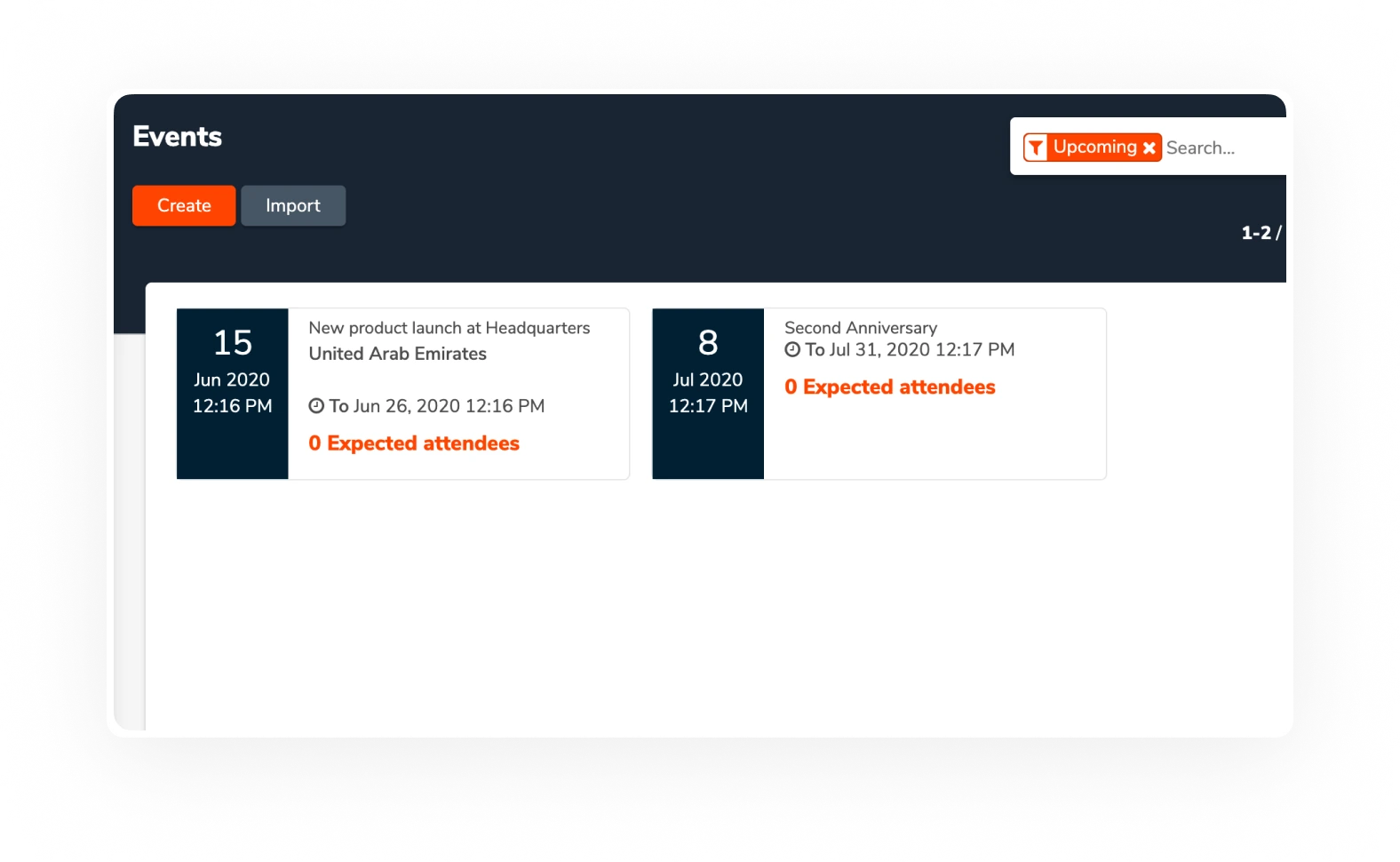

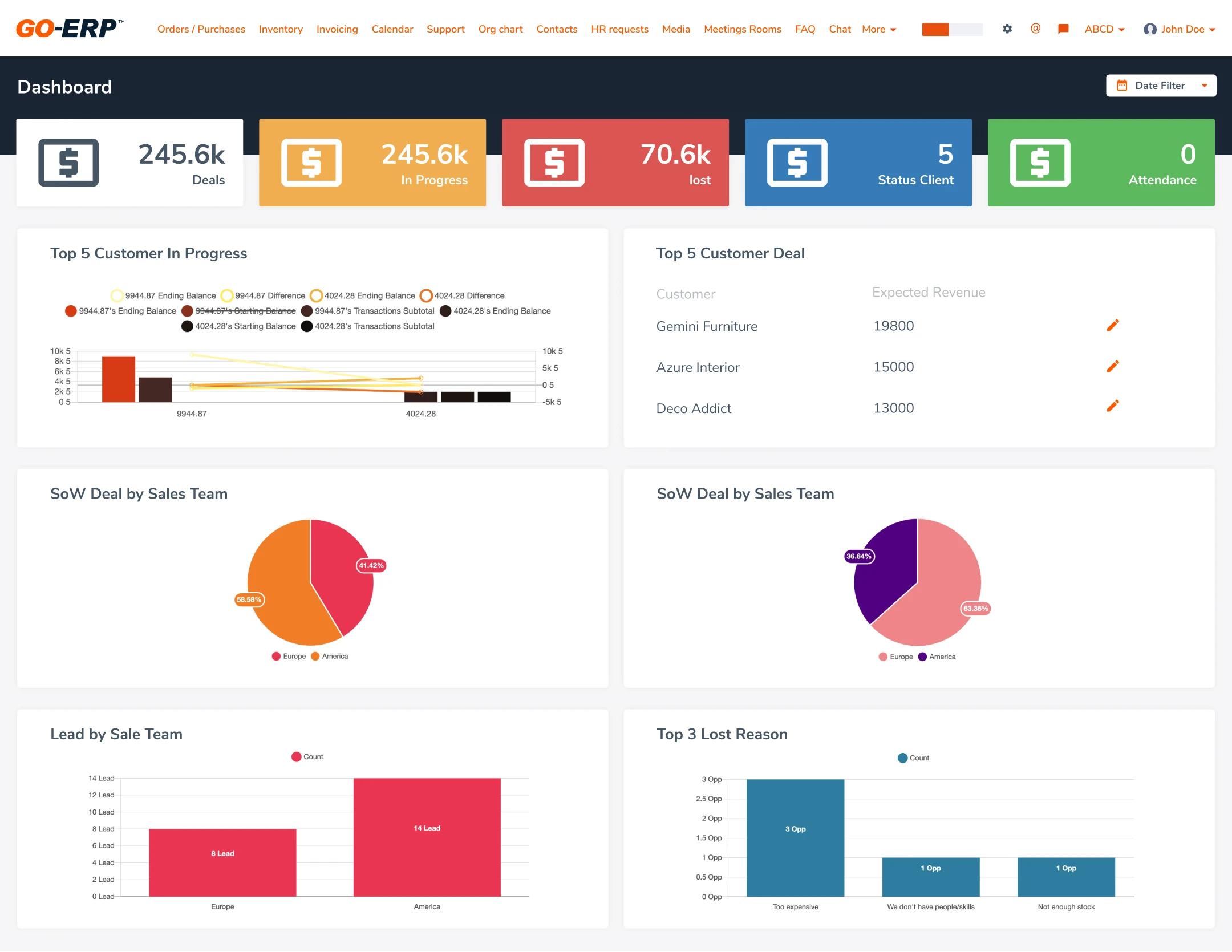

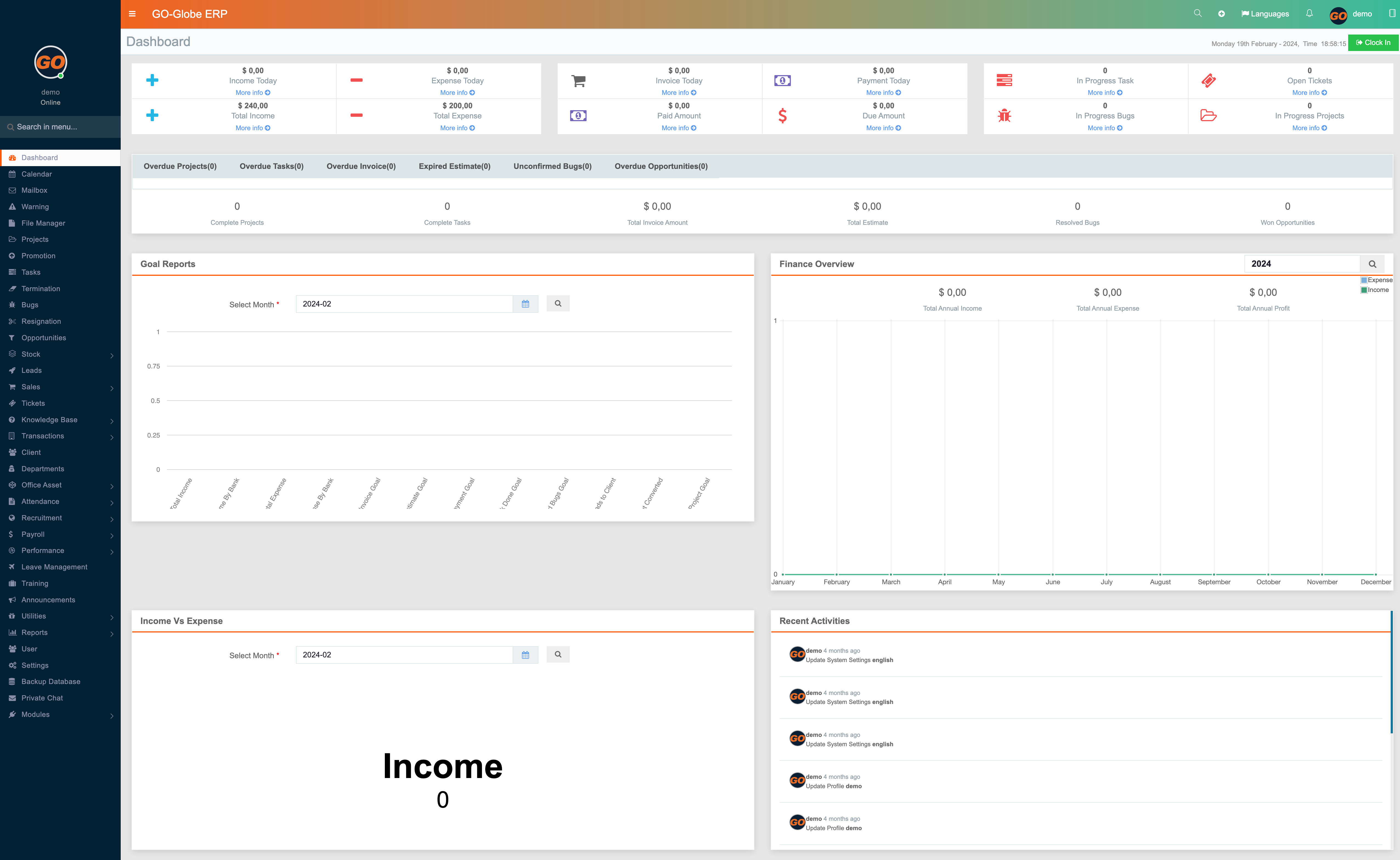

You have tons of data but struggle to use it. Our system gives you clear dashboards that show what matters. Even better, you can just ask questions in plain language like "Why did Line 3 slow down last Tuesday?" and get instant answers.

The AI also predicts what will happen under different scenarios, so you can make decisions based on facts instead of gut feelings.

Our system talks directly to your PLCs, robots, automated vehicles, and other equipment. Everything works together seamlessly. When the ERP system sends a production order, your machines receive it instantly and report back when it's done. You get complete visibility and control without manual data entry.

Energy is expensive, and sustainability matters more every year. Our Industry 4.0 AI ERP Frankfurt tracks your energy use, finds ways to save, and schedules production when electricity is cheapest. It also tracks your carbon footprint and helps you meet Germany's ambitious environmental goals.

Most manufacturers cut energy costs by 15-25% after implementation

Your Operations Will Run Smoother

You'll see 15-25% better equipment performance, finish jobs 20-30% faster, and cut operating costs by 25-35%. These aren't small improvements—they directly boost your bottom line and make you more competitive.

Your Quality Will Impress Everyone

Defects drop by 40-60%. Quality costs fall by 50-70%. Customer complaints basically disappear. That's the kind of quality that builds your reputation and justifies premium prices.

You'll Handle Change Better

Market changes? Customer rush orders? Supply chain problems? Your automotive AI ERP Germany helps you adapt quickly without sacrificing efficiency or quality. You can efficiently make small batches of different products and respond to whatever your customers need.

You'll Meet Your Sustainability Goals

Cut material waste by 20-30%. Reduce energy use by 15-25%. Get the detailed reports you need for regulations and investors. Going green while staying profitable isn't just possible—it's built into the system.

Germany invented the term "Industrie 4.0" and leads the world in making it real. Frankfurt gives you unique advantages: you're close to major car makers, surrounded by innovative suppliers, and have access to world-class universities and research centers.

The German government actively supports digital transformation through Plattform Industrie 4.0, which provides frameworks and best practices. When you implement our intelligent manufacturing ERP Frankfurt, you're tapping into this entire ecosystem of support and expertise.

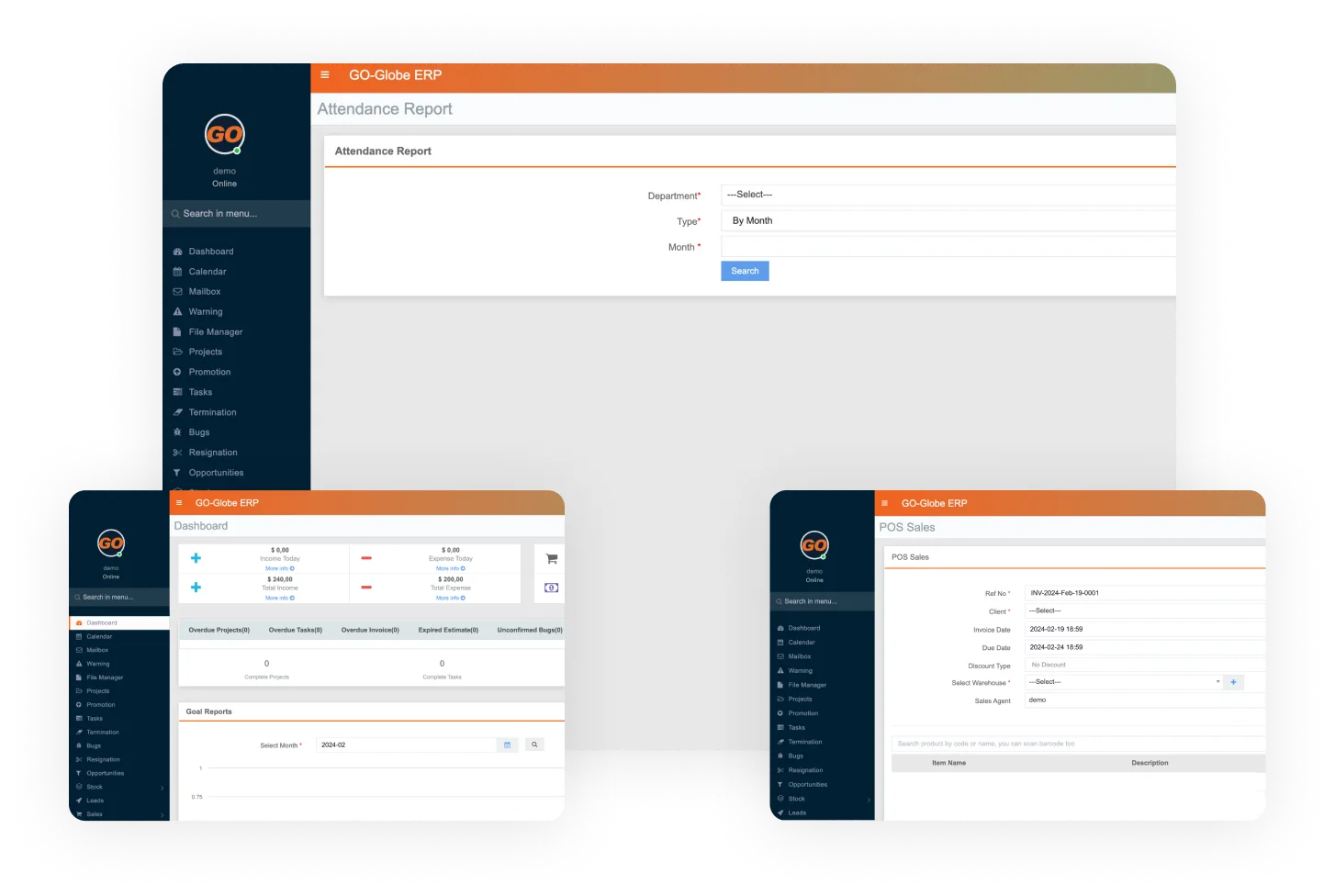

First, we study how your factory actually works. We look at your processes, equipment, current systems, and business goals. For automotive manufacturers, we examine specific requirements like IATF 16949 quality standards and VDA compliance. This tells us exactly what you need and where you'll get the biggest improvements.

Based on what we learn, we create a clear plan that balances quick wins with long-term transformation. You'll see which improvements come first, what they'll cost, and how we'll measure success. No vague promises, just a concrete plan.

This is where we map out how everything connects. Your IoT sensors, production equipment, and business systems all need to work together smoothly. We design the complete architecture including cybersecurity, so everything is protected from day one.

Every factory is different. We configure our smart ERP Frankfurt to match your specific needs—whether you make discrete products, run continuous processes, or do batch production. We build in your industry standards, regulatory requirements, and the way your organization actually works.

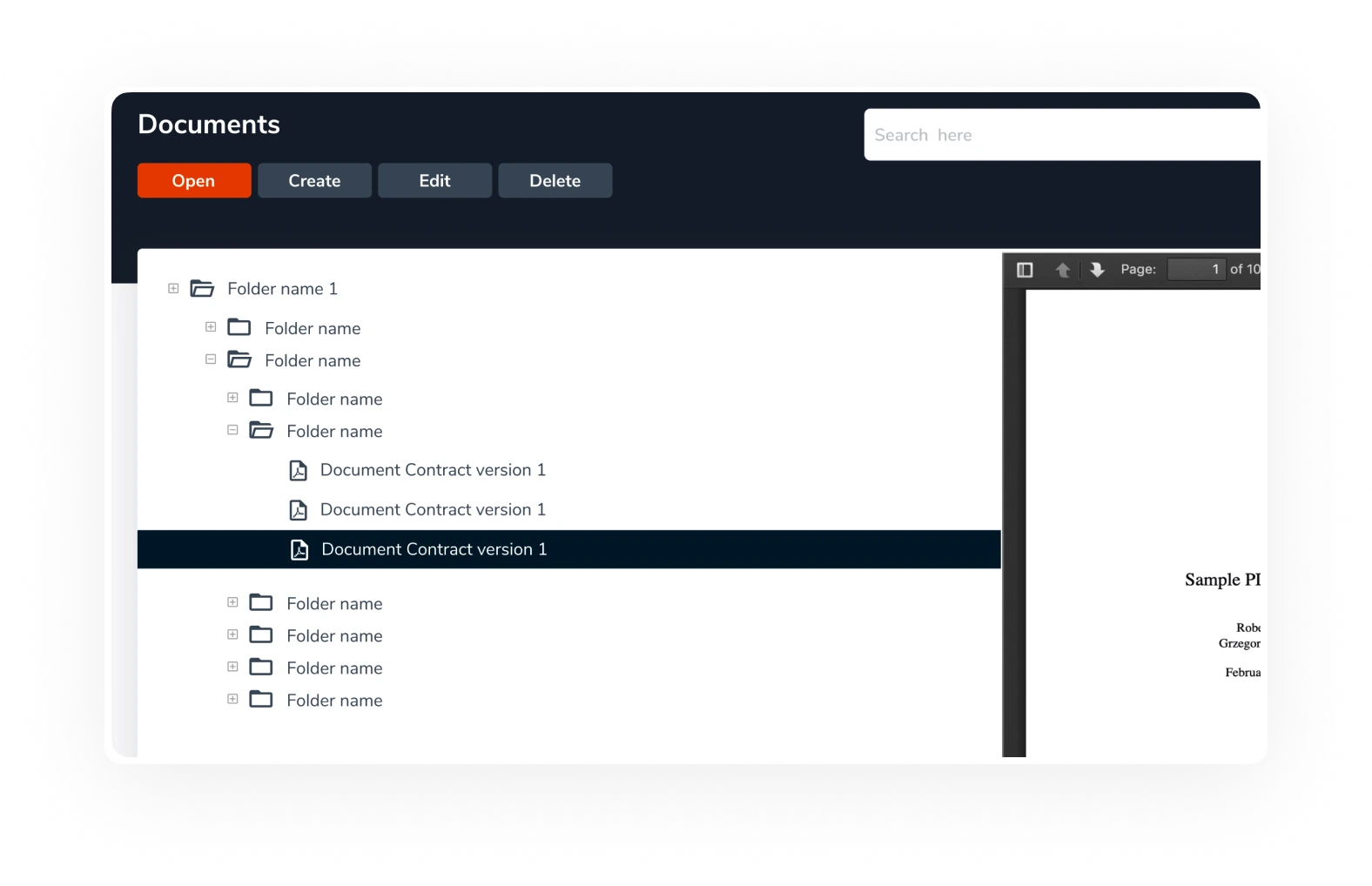

You've invested in equipment and systems. We make sure they all work together. Our system connects to legacy ERP platforms, manufacturing execution systems, quality systems, PLCs from any manufacturer, and warehouse management systems. We use standard industrial protocols so everything communicates reliably.

Technology only works if people use it well. We provide complete training for everyone—from shop floor operators to executives. Training is practical and role-specific, focused on how people will use the system in their daily work. We provide materials in both German and English.

We typically start with a pilot operation, prove the value, then expand progressively to other lines or plants. This approach manages risk and builds confidence. Most organizations see initial capabilities live within 4-6 months, with full deployment taking 12-24 months depending on size and complexity.

Automotive Manufacturing

Our automotive AI ERP Germany handles mixed-model production, just-in-sequence logistics, VDA labeling, and all the complex requirements German car makers demand.

Machinery and Equipment

Make-to-order and engineer-to-order processes need sophisticated project management and configuration control. We've got you covered.

Electronics Manufacturing

Fast product lifecycles and complex supply chains require specialized tools. Our system manages it all while preventing counterfeit components.

Process Industries

Chemical, pharmaceutical, and food manufacturers get batch management, recipe control, and the complete traceability regulations require.

Industrial cybersecurity is serious business. Our enterprise AI ERP Germany includes multiple layers of security, complies with IEC 62443 standards, and meets GDPR requirements for data protection. We use encryption, continuous monitoring, and regular security audits to keep everything protected.

We work with your IT security team to integrate with your existing security infrastructure and follow your policies.

Here's what manufacturers typically achieve with our manufacturing AI ERP Frankfurt:

Equipment runs 15-25% better. Production gets 20-30% faster. Costs drop 25-35%. Defects fall 40-60%. Inventory goes down 20-30%. Energy use drops 15-25%. Unplanned downtime decreases 30-50%. On-time delivery hits 95% or better.

Most importantly, you'll see positive ROI within 18-24 months. That's real money back in your pocket, not to mention the competitive advantages you'll gain.

How long will this take?

Full implementation typically takes 12-24 months, but we work in phases. You'll see initial capabilities within 4-6 months and start getting value right away. We don't make you wait years to see results.

Will it work with our existing equipment?

Yes. We connect to virtually any industrial equipment using standard protocols like OPC UA, MQTT, and Modbus. Whether you have Siemens, Allen-Bradley, or Mitsubishi PLCs, we'll make them work together.

What about cybersecurity risks?

We take security seriously with multiple protection layers, industry-standard compliance, and continuous monitoring. Your systems stay protected from threats while remaining fully functional.

Can we afford this?

Think of it as an investment that pays for itself. Most organizations break even within 18-24 months through cost savings and efficiency gains. After that, it's pure profit plus all the strategic advantages.

How does this help with sustainability?

You'll cut energy use by 15-25%, reduce waste by 20-30%, and get detailed carbon tracking for reports. Meeting environmental goals while improving profits isn't a trade-off anymore.

Leading Frankfurt manufacturers are already transforming their operations with Go-Globe's Industry 4.0 AI ERP solutions. They're cutting costs, improving quality, and staying ahead of competitors.

We'll show you exactly how our system can work for your factory. No generic demos—we'll discuss your specific challenges and create a custom roadmap for your transformation.

Visit Go-Globe to schedule your consultation and start your journey toward manufacturing excellence.