Munich is Germany's car capital. BMW is here. Top suppliers are here. Great engineers are here. But most companies use ERP systems that only track what already happened. That's not enough anymore.

GO-Globe's automotive AI ERP Munich helps you see what's coming next. Our smart system predicts demand, plans production better, fixes supply chain problems before they happen, and shows you the numbers that matter right now.

Your current ERP tracks transactions and stores data. That was fine 10 years ago. Today, automotive is crazy complex. Thousands of car configurations. Suppliers all over the world. Parts arriving just in time. Constant changes. Tight margins.

You need a system that thinks ahead. Our automotive AI erp Germany predicts what customers will want, figures out the best production schedule, manages your supply chain automatically, shows you profit and costs in real time, and gets smarter every day.

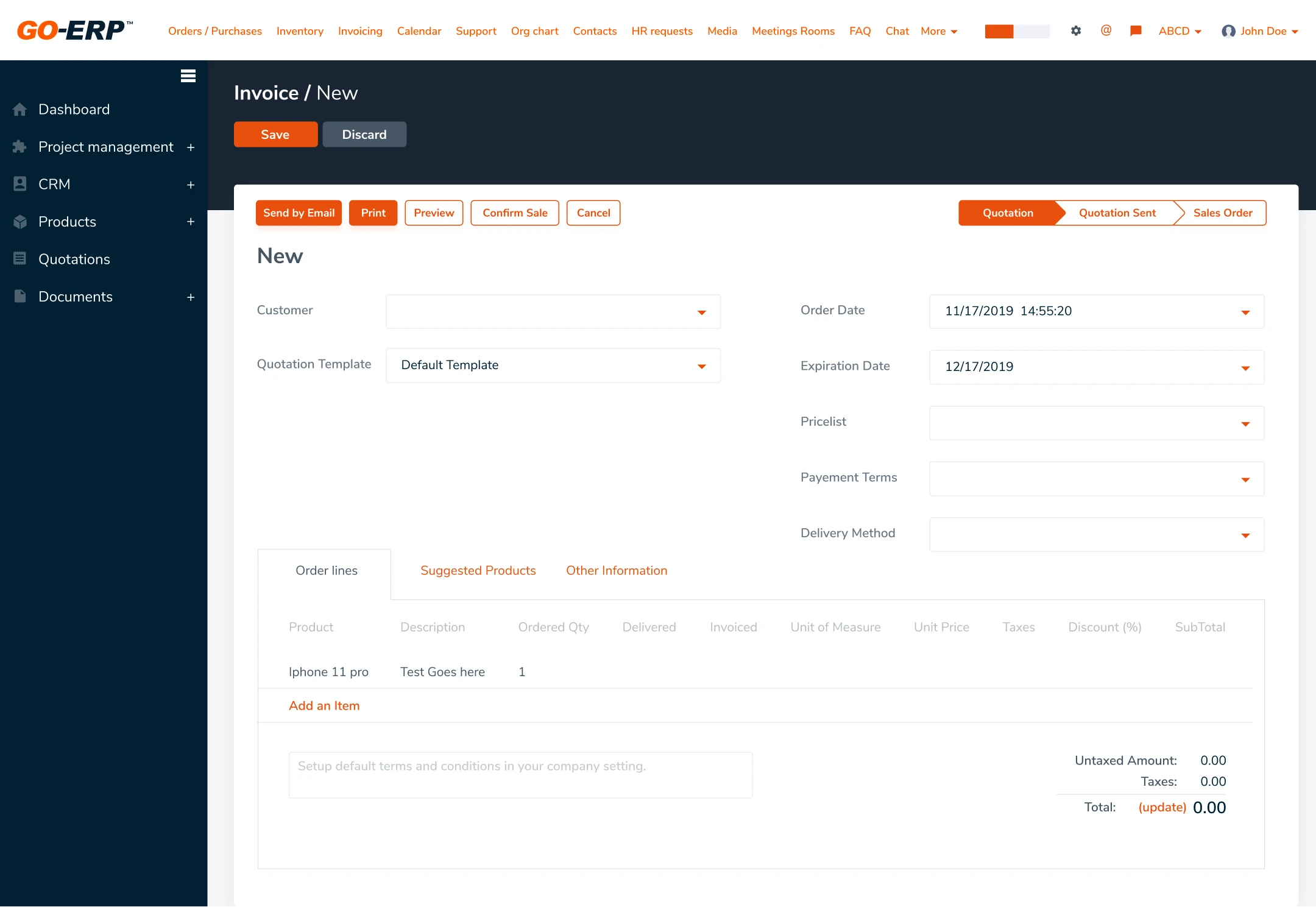

Plans Production Better

Building different car models on the same line is complicated. Our manufacturing ERP AI Munich uses AI to create the best production plan, coordinate multiple factories, switch between models faster, and adjust when things go wrong. You get 25-35% better on-time delivery and 20-30% less inventory sitting around.

Manages Your Supply Chain

Just-in-time means you only have hours of parts. Just-in-sequence means parts arrive in exact order. Our industry 4.0 ERP Germany predicts what you'll need, watches supplier performance, buys smart, optimizes shipping, and warns you about problems early. Supply chain costs drop 15-25%. Deliveries hit 98%+.

Catches Quality Problems Early

Quality mistakes cost billions. Warranties. Recalls. Rework. Our intelligent ERP Munich predicts problems before they happen, figures out what's causing defects, tracks quality costs, and helps suppliers improve. Quality costs drop 40-60%. Warranty costs fall 30-50%.

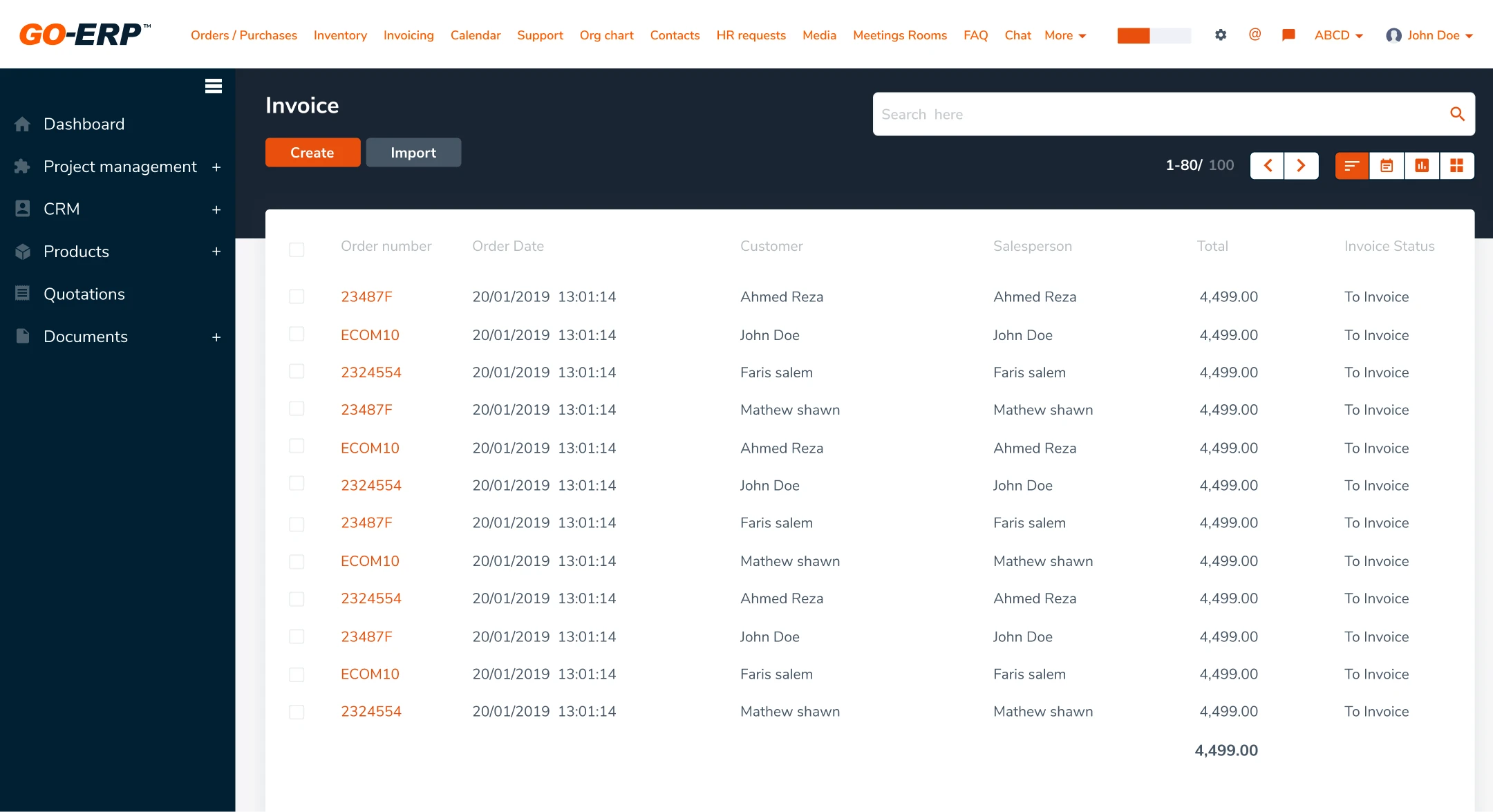

Shows You Real Money Numbers

Know exactly what's making or losing money. Our enterprise AI ERP Germany predicts cash flow, closes books faster, shows profit by product and customer, and finds ways to save money. You get 30-40% better forecasts and close books 40-50% faster.

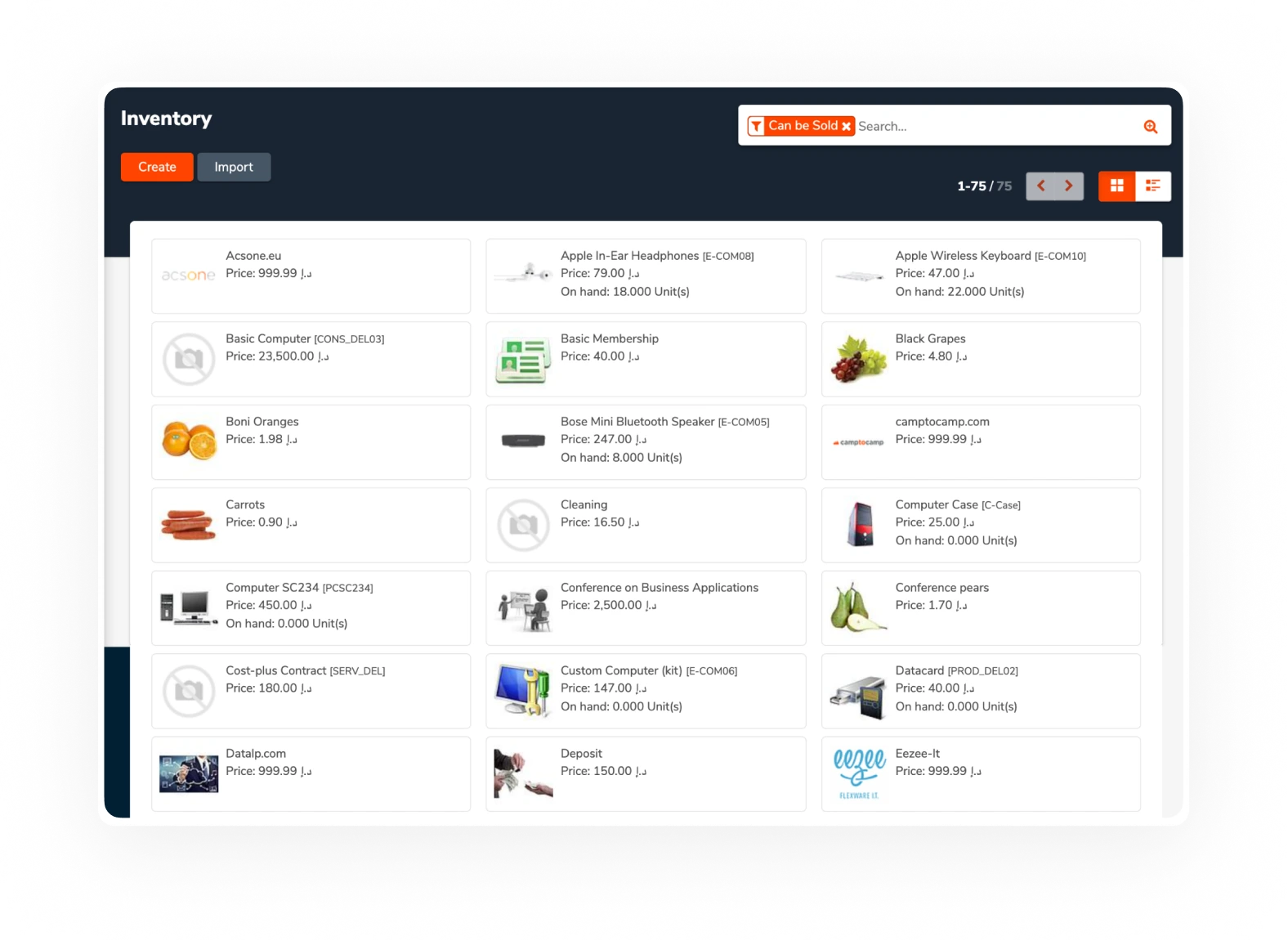

Manages Inventory Smart

Less inventory means more cash. But you can't stop production waiting for parts. Our smart automotive ERP Munich figures out exactly how much to keep, orders automatically at the right time, and makes sure you never run out. Inventory drops 20-30%. Parts availability hits 99%+.

Handles Changes Easier

Cars constantly change. Better quality. Lower costs. New regulations. Our automotive AI ERP Munich spreads changes through all systems automatically, shows you what the change affects, and tracks everything. Changes happen 30-50% faster with fewer problems.

Helps Service and Sales

After-sales makes real money. Our system predicts which cars need service, spots warranty problems early, keeps the right parts in stock, and understands what customers want. Parts availability improves 20-30%. Customers are happier.

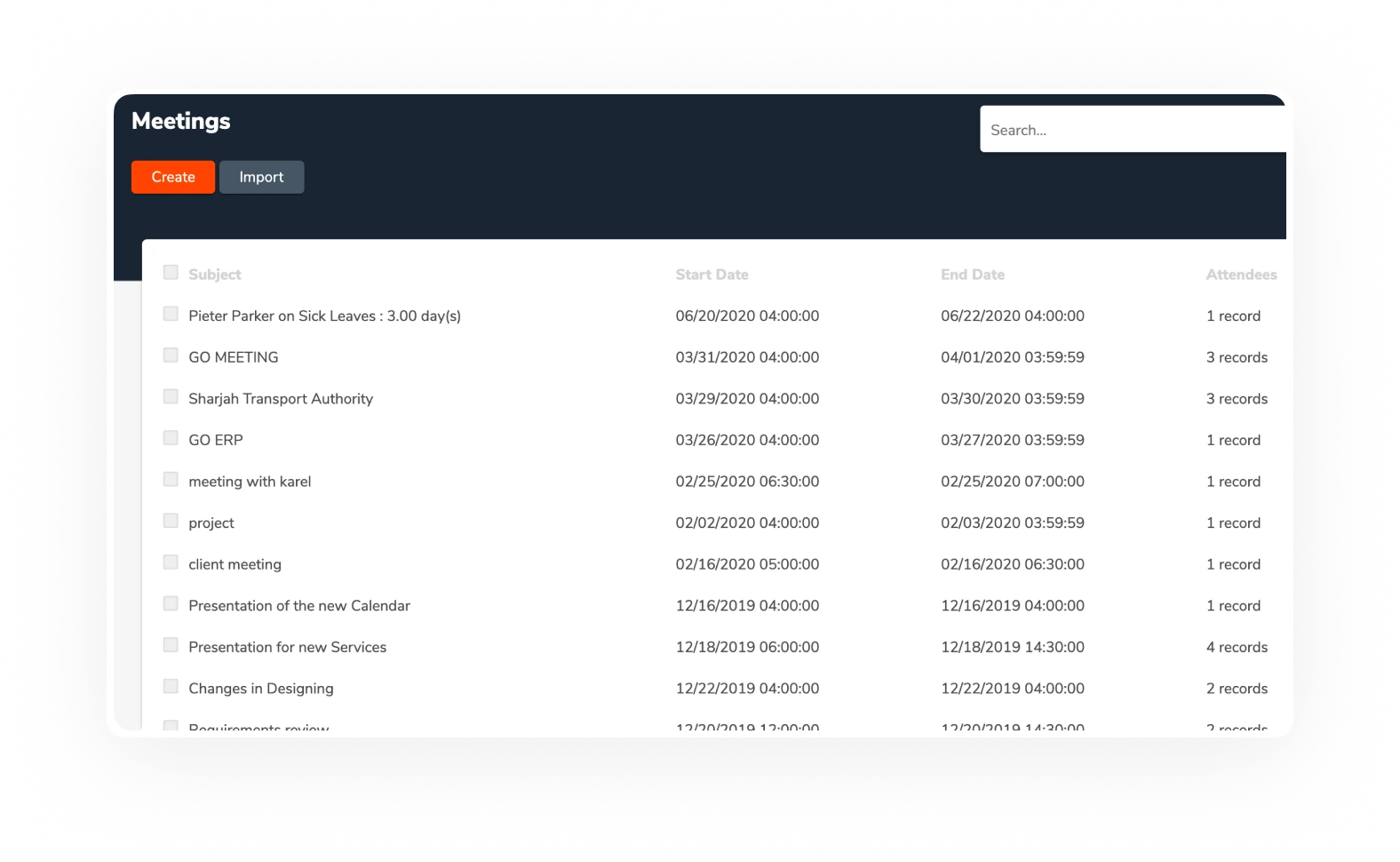

Gives You Quick Answers

No waiting for reports. Our system shows you what's happening now. Ask questions in plain language. See predictions. Get alerts when something needs attention. Make decisions 40-60% faster.

Planning gets 25-40% more accurate. Lead times drop 20-35%. Costs fall 15-25%. Supply chain costs down 20-30%. Quality costs down 40-60%. Warranty costs down 30-50%. Books close 40-50% faster. Inventory frees up 15-25% more cash.

Most companies see positive return within 18-24 months.

BMW sets high standards here. Suppliers must meet them. Technical University trains people who expect good systems. Works councils need to approve technology changes. You need transparent systems that respect employees.

German automotive has strict rules. BaFin financial regulations. GDPR privacy laws. IATF 16949 quality standards. VDA automotive standards. BMW, Audi, and Mercedes each have their own requirements.

Our automotive AI erp Germany handles all of this built in, not added later.

OEMs, Tier 1 suppliers, Tier 2/3 suppliers, automotive electronics companies, and electric vehicle manufacturers. Whether you're making traditional cars or switching to electric.

ISO 27001 certified. GDPR compliant. IATF 16949 integrated. VDA compliant. Automotive cybersecurity. Full encryption. Complete audit trails. Business continuity planning.

We Study Your Business: Look at your current systems, processes, data, and automotive requirements.

We Make a Plan: Balance quick wins with long-term goals. Clear timeline and metrics.

We Build It Right: Meet all automotive standards. IATF 16949. VDA. OEM requirements. Full traceability.

We Add Intelligence: Machine learning predicts things. Natural language lets you ask questions. Computer vision checks quality. Everything gets smarter.

We Connect Everything: Links to your MES, PLM, quality systems, suppliers, dealers, and BMW/Audi/Mercedes systems.

We Test Thoroughly: Pilot programs prove it works. Usually 3-4 months of testing.

We Train Everyone: Programs in German and English. Works with works councils. Changes processes to work better.

We Keep Improving: Ongoing support. Updates. New features. Always getting better.

Leading Munich automotive companies already use GO-Globe's automotive AI ERP Munich systems.

Takes 12-24 months for full systems, 6-9 months for parts. We can start wherever you are.

Visit GO-Globe to schedule a consultation.

Built specifically for automotive. IATF 16949. VDA standards. BMW/Audi/Mercedes requirements. Just-in-sequence logistics. Thousands of configurations. Complete traceability. Plus AI that predicts and optimizes.

Full implementation: 18-24 months. Single modules: 6-9 months. We recommend starting small and expanding.

Yes. We connect with SAP and all other automotive systems. Can enhance your current SAP or work alongside it

Yes. Full traceability, documentation, quality gates, PPAP support, everything you need. Built in, not added on

Yes. We understand BMW requirements, works councils, VDA standards, and German business culture. Support in German and English.

We work with them from day one. Transparent about data use. Follow German labor laws. Show how it helps employees, not replaces them.

Better planning, lower inventory, cheaper supply chain, fewer defects, faster decisions. Typical return within 18-24 months. Plus strategic benefits for long-term success.

Yes. Battery supply chains, high-voltage safety, EV-specific parts, different cost structures, new regulations, software management, charging infrastructure. Works for traditional and EV together