The Frankfurt Rhine-Main region is packed with manufacturing excellence automotive suppliers, precision engineering, chemical producers, pharmaceutical companies. But here's the truth: most factories still manage production the old way, leaving massive efficiency on the table.

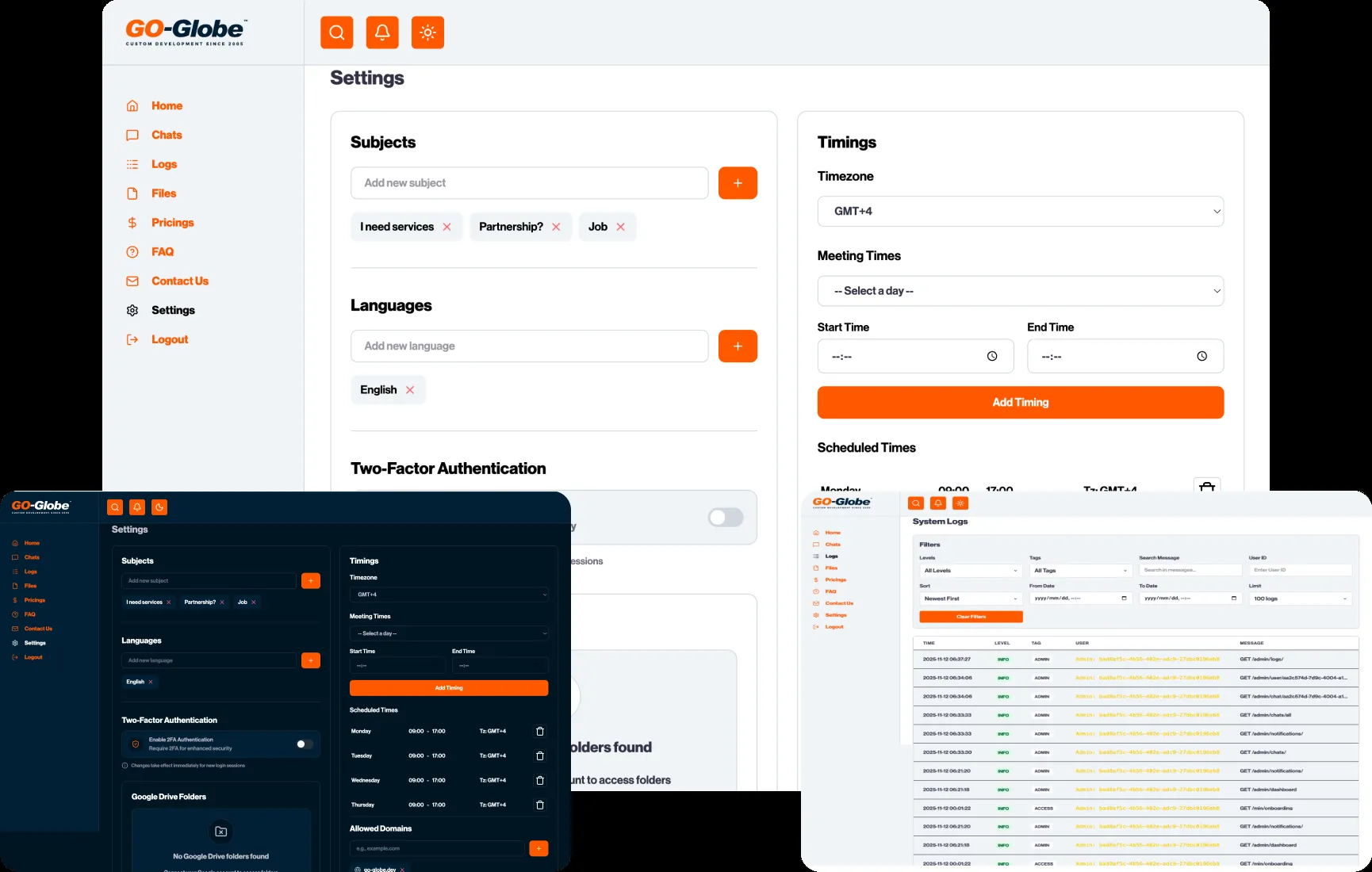

GO-Globe's AI production management Frankfurt changes everything. We help manufacturers use artificial intelligence to plan production smarter, catch quality issues before they happen, predict equipment failures, and optimize every aspect of operations. This is real Industry 4.0—not just buzzwords.

Traditional production management relies on human planners, static schedules, spot-checking quality, and fixing problems after they happen. It worked fine 20 years ago. Today? Not so much.

Our industry 4.0 AI Frankfurt approach transforms this completely. Real-time data flows from sensors and equipment. Predictive analytics spot problems before they impact production. The system makes smart decisions automatically within your parameters. Schedules adapt dynamically to changing conditions. And everything keeps learning and improving from operational data.

This isn't incremental improvement—it's the difference between reacting to problems and preventing them entirely

Production planning gets complex fast when you have product variety, customer customization, shared resources, and supply chain dependencies. Our smart factory AI Germany analyzes thousands of variables at once—customer demand, machine capacity, material availability, workforce schedules, quality requirements, energy costs, maintenance windows.

Machine learning generates optimal schedules that maximize output, minimize changeovers, balance workloads, and hit delivery dates. When something goes wrong—equipment breaks, materials run short, rush order comes in—the system automatically reschedules to minimize impact.

Most manufacturers improve on-time delivery by 20-30% while cutting inventory costs 15-25%.

Finding defects after production wastes money on rework and scrap while damaging your reputation. Our AI production management Frankfurt prevents defects instead of just catching them.

The system watches production parameters in real-time temperatures, pressures, speeds, tool wear, material properties. Machine learning spots conditions that lead to defects. When parameters drift toward trouble, the system alerts operators or adjusts processes automatically to stay within specs.

Computer vision inspects products with superhuman accuracy, catching defects invisible to humans. Statistical process control enhanced by AI detects subtle trends before they produce bad parts.

Defect rates typically drop 40-60% while quality costs plummet.

Unplanned downtime costs millions in lost production, emergency repairs, and delayed deliveries. Our intelligent production Germany solutions use predictive maintenance that analyzes equipment condition from IoT sensors—vibration patterns, temperatures, sounds, power consumption.

Machine learning predicts failures days or weeks early, letting you schedule maintenance during planned downtime instead of scrambling with emergency repairs. The system optimizes maintenance schedules, prioritizes activities by business impact, and extends equipment life through optimal operating conditions.

Most organizations cut unplanned downtime by 30-50%, reduce maintenance costs 20-30%, and improve overall equipment effectiveness by 15-25%.

Traditional approaches give you delayed, summarized information. Our MES AI system Frankfurt provides real-time monitoring with comprehensive dashboards showing current production status across all lines, equipment performance, work-in-progress locations and quantities, quality metrics and trends, and bottleneck identification.

The system processes data from shop floor equipment, MES systems, ERP platforms, and quality systems—creating unified views. Alerts notify you immediately when issues arise so you can respond fast.

This transparency improves decision-making speed by 40-60% while reducing production variability.

The most transformative part? The system continuously improves production without constant human intervention. Machine learning analyzes operational data, identifies optimization opportunities—better process parameters, smarter sequences, improved schedules, optimized inventory positioning.

The system simulates proposed changes, predicts outcomes, implements improvements within your boundaries, monitors results, and learns from outcomes. This continuous improvement runs 24/7 at speeds humans can't match, delivering gains that compound into major competitive advantages.

You need materials available for production, but excess inventory ties up cash. Our manufacturing AI automation Frankfurt optimizes inventory through demand forecasting, supplier performance monitoring, automated reordering, smart inventory positioning, and just-in-time coordination.

The system manages thousands of part numbers across multiple locations, preventing stockouts while minimizing inventory investment. Most manufacturers reduce carrying costs by 20-30% while improving material availability above 98%.

Energy represents major manufacturing costs, and sustainability requirements keep intensifying. Our smart manufacturing Germany solutions include intelligent energy management that monitors consumption patterns, coordinates production with energy pricing, manages peak loads, optimizes parameters for efficiency, and tracks carbon footprints.

Machine learning finds energy-saving opportunities that maintain production while reducing consumption. Most manufacturers cut energy costs by 15-25% while advancing sustainability aligned with Germany's Energiewende.

Skilled workers remain central to manufacturing despite automation. Our AI production management Frankfurt enhances workforce effectiveness through intelligent work assignment matching skills to tasks, training identification, productivity analysis, safety monitoring, and collaboration tools.

The system respects works council requirements while improving performance. Productivity typically jumps 15-25% while job satisfaction improves.

Operations Excellence: Manufacturers see 20-35% better equipment effectiveness, 25-40% shorter lead times, 30-45% less inventory sitting around, and 15-25% better labor productivity. These gains hit your bottom line directly.

Quality Gets Way Better: Defects drop 40-60%. Quality costs (rework, scrap) fall 50-70%. Customer complaints basically disappear. First-pass yield improves 15-25%. This quality excellence strengthens your reputation and supports premium pricing.

More Flexibility: The smart factory AI Germany lets you respond quickly to customer changes, engineering modifications, supply disruptions, and demand swings. You handle high-mix production efficiently, implement changes fast, and respond to rush orders without chaos.

Costs Go Down: Beyond labor savings, you'll see lower inventory costs, reduced energy consumption, less material waste, minimized quality costs, and optimized maintenance spending. Total operational costs typically drop 20-35%.

Sustainability Improves: Material waste decreases 20-30%. Energy consumption falls 15-25%. Carbon emissions drop significantly. You get comprehensive sustainability reporting. These improvements align with EU Green Deal objectives and enhance your reputation.

Competitive Edge: Manufacturers with advanced AI capabilities differentiate through operational excellence, quality performance, delivery reliability, and innovation capacity. This attracts customers, enables premium pricing, and defends against low-cost competitors.

Germany pioneered Industry 4.0 through the "Plattform Industrie 4.0" initiative combining government support, industry collaboration, and research excellence. Frankfurt's Rhine-Main location gives you access to automotive clusters, precision engineering companies, chemical industry, and sophisticated suppliers forming an innovation ecosystem.

German manufacturing culture emphasizes engineering excellence, quality precision, continuous improvement, and operational discipline—values that align perfectly with AI production management's data-driven approach. Fraunhofer institutes and technical universities provide deep expertise and talent.

Plus, Germany's skilled workforce and apprenticeship system create workers who can leverage advanced technologies effectively. Works councils ensure implementations consider employee interests, creating sustainable transformations with broad support.

We analyze your production processes, equipment capabilities, existing automation, data infrastructure, quality management, organizational structure, and business objectives. For automotive suppliers, we assess IATF 16949 compliance, customer requirements, and just-in-sequence logistics.

We evaluate your current maturity across digitalization, connectivity, data analytics, automation sophistication, and organizational readiness. This identifies gaps and priorities for your transformation roadmap.

We design comprehensive architectures connecting shop floor to enterprise systems—IoT sensor networks, edge computing, manufacturing execution systems, ERP integration, and the AI layer providing intelligence across operations. Everything includes cybersecurity, scalability, and future expansion capabilities.

We begin with focused pilot implementations targeting specific production lines or use cases. Pilots demonstrate value quickly, allow learning and refinement, validate approaches, and build confidence. Each pilot has clear success criteria and performance measurement.

The MES AI system Frankfurt connects with your existing PLCs (Siemens, Allen-Bradley, Mitsubishi, others), SCADA systems, quality systems, ERP platforms like SAP, and warehouse management. We use standard industrial protocols, conduct comprehensive testing, and ensure reliable operation.

Success requires change management including leadership engagement, works council consultation, communication strategies, comprehensive training for operators/engineers/planners/managers, and process redesign. We develop training in German, provide hands-on practice, and support adoption throughout.

After successful pilots, we expand across additional lines, plants, or business units. This phased approach manages risk, allows continuous learning, and demonstrates increasing value.

Industry 4.0 is continuous. We provide ongoing support including monitoring and optimization, model retraining, capability enhancements, technology updates, and strategic reviews identifying new opportunities.

Machine Learning: Random forests for decisions, neural networks for patterns, time series forecasting, optimization algorithms, and reinforcement learning for autonomous control.

IoT and Sensors: Comprehensive networks collecting temperature, pressure, vibration, acoustic, visual, position, speed, power, and environmental data.

Computer Vision: AI-powered inspection at superhuman speed and accuracy, assembly verification, part tracking, defect classification, and process monitoring.

Digital Twins: Virtual replicas enabling simulation, what-if analysis, optimization in virtual environments, training, and maintenance planning without disrupting production.

Robotics Integration: Coordination of collaborative robots, automated guided vehicles, automated storage systems, and CNC machines based on production requirements.

Edge and Cloud Computing: Edge processes time-critical data locally for real-time control. Cloud provides centralized analytics, model training, and coordination across facilities.

Automotive: Mixed-model assembly scheduling, just-in-sequence coordination, zero-defect quality, traceability, IATF 16949 compliance.

Precision Engineering: Complex job shop scheduling, tool management, tight tolerance quality control, make-to-order capacity planning.

Chemical/Process: Batch process optimization, recipe management, quality monitoring, regulatory compliance, environmental monitoring.

Electronics: High-speed line optimization, component traceability, yield improvement, test analytics, counterfeit prevention.

Pharmaceutical: GMP-compliant documentation, quality monitoring, validation support, serialization, regulatory reporting.

Manufacturing systems face increasing cyber threats. Our smart factory AI Germany includes:

IEC 62443 compliance, network segmentation isolating production systems, encrypted communications, role-based access controls, threat monitoring, security patch management, incident response procedures, backup and recovery, compliance documentation, and works council coordination.

Organizations typically achieve:

Equipment effectiveness improves 20-35%. Lead times drop 25-40%. Defects decrease 40-60%. Unplanned downtime falls 30-50%. Energy consumption drops 15-25%. Inventory optimizes 20-30%. Labor productivity jumps 15-25%. Quality costs plummet 50-70%. On-time delivery improves 20-30%.

Most importantly, you'll see positive ROI within 12-24 months.

Leading Frankfurt and Rhine-Main manufacturers have already transformed their production operations with GO-Globe's AI production management solutions. Better efficiency, higher quality, lower costs, and stronger competitive positioning.

Implementation typically takes 6-18 months depending on your facility size and complexity. We offer flexible approaches whether you're starting your Industry 4.0 journey or advancing existing initiatives.

Visit GO-Globe to schedule your consultation and begin your journey toward manufacturing excellence in the Fourth Industrial Revolution.

Traditional MES collects data and tells you what happened. Our AI production management Frankfurt predicts what will happen, optimizes decisions automatically, learns continuously, and adapts dynamically. MES provides visibility. AI production management provides intelligence.

Focused pilots take 3-6 months. Comprehensive facility-wide implementations span 12-18 months including pilots and progressive rollout. We recommend phased approaches demonstrating ROI quickly then expanding systematically.

Yes. We connect with any industrial equipment using standard protocols—OPC UA, MQTT, Modbus, PROFINET, EtherNet/IP, and others. We integrate with PLCs from all manufacturers, SCADA systems, existing MES platforms, SAP, and quality systems. No wholesale equipment replacement needed.

We address German-specific requirements including VDI and DIN standards compliance, integration with Siemens PLCs and SAP, works council involvement, German language support, and alignment with German manufacturing culture emphasizing quality and precision. We understand BetrVG labor law, GDPR requirements, and German preferences for proven reliability.

We implement defense-in-depth architecture with IEC 62443 compliance, network segmentation, encrypted communications, role-based access controls, audit logging, continuous threat monitoring, and incident response procedures. We work with your IT security teams ensuring integration with corporate security infrastructure.

Comprehensive support including leadership workshops, works council engagement, operator training, engineer and planner training, maintenance team training, and continuous improvement team training. Materials come in German and English with hands-on practice and post-implementation support.

Most manufacturers achieve positive ROI within 12-24 months. Typical results include 20-35% better equipment effectiveness, 30-45% less inventory, 40-60% fewer defects, 30-50% less unplanned downtime, and 15-25% better productivity. Beyond direct savings, you get improved competitiveness and better customer satisfaction.

Energy consumption drops 15-25%, material waste decreases 20-30%, you get emissions tracking and reporting, circular economy support, and comprehensive ESG reporting. These align with EU Green Deal and Germany's Energiewende while creating competitive advantages.